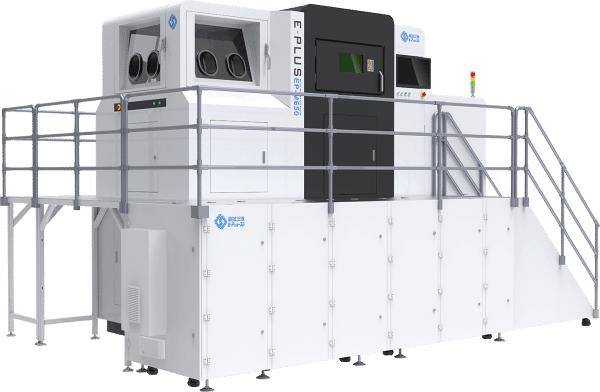

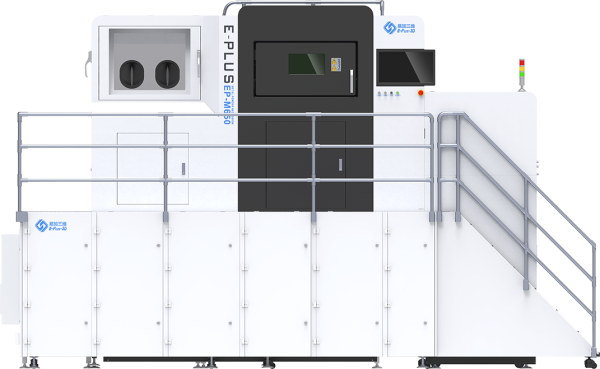

Quad Laser Large Size Metal Additive Manufacturing System

דף הבית » 3D Hardware » Eplus3D » EP-M650 Metal 3D Printer

The EP-M650 is designed to operate with various metal powders such as Titanium, Aluminium and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defence industry. Using MPBF (Metal Powder Bed Fusion) technology and a quad laser system and large 655x655x800mm print volume, assures optimized and efficient results.

Capable of printing large parts with increased speed and precision, the EP-M650 uses 4 lasers to simultaneously print at speed of up to 120m/s. Print time can be further reduced using layer thickness of 60 um, speeding printing time significantly. Precise calibration assures accurate parts reproduction and optimized gas flow ensures effective removal of dust and splatter. Coherent laser and optical elements provide part deviation less the .1mm.

Intuitive, User-friendly interface software enables one-click printing with full control of print parameters and full job information and reporting.

Built-in safety, prevent mis-operation, electric shock, fire, waste and pollution, recovering unused material. Real-time system environment monitors print, for safe and reliable operation.

Eplus3D offers its customers technical consulting services including data evaluation and application development. Full assistance is offered to customers as new materials are introduced.

Machine Model | EP-M650 |

Build Chamber (XxYxZ) | 650 x 650 x 800 mm (25.59 x 25.59 x 31.49 in)(height incl. build plate) |

Optical System | Fiber Laser 4 x 500 W / 4 x 700 W / 4 x 1000 W |

Spot Size | 70~120 µm |

Max Scan Speed | 9 m/s |

Layer Thickness | 20~120 µm |

Theoretical Printspeed | Up to 190 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | Substrate heating temperature 200℃ |

Power Supply | 380 V, 65 A, 50 / 60 Hz, 30 kW |

Gas Supply | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm |

Dimension (WxDxH) | 6800 x 3945 x 3785 mm |

Weight | 15000 kg |

Software | EP-Hatch, EP Control |

Input Data Format | STL file or another convertible format |

WhatsApp us

Thanks for signing up