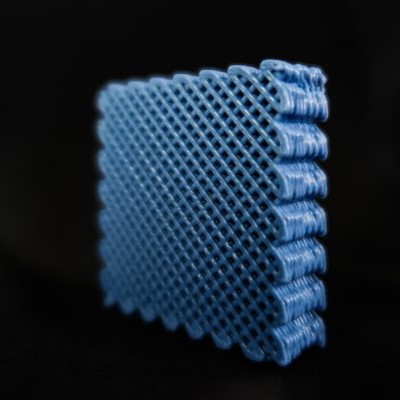

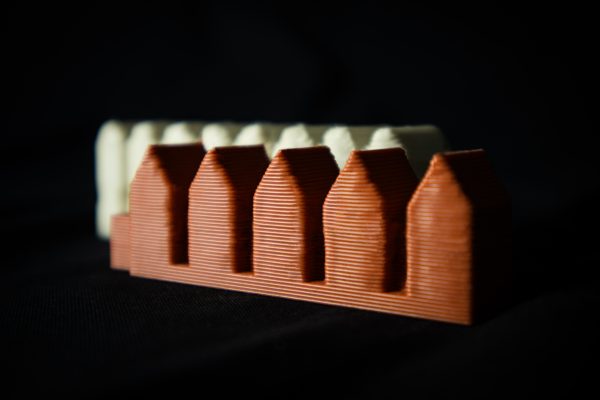

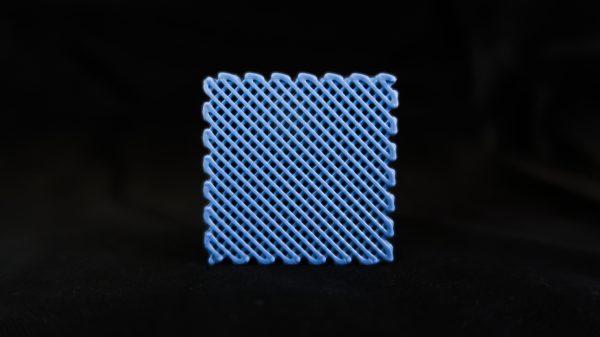

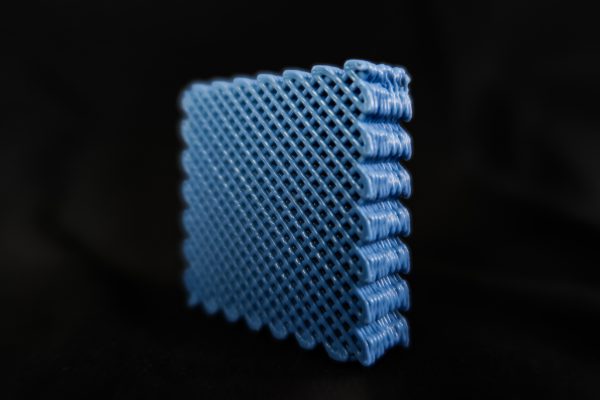

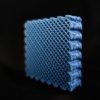

Liquid silicone is perfect for DIW because its low viscosity allows for precise extrusion of complex structures. Additionally, it cures at low temperatures, making it suitable for a wide range of applications, such as medical devices and soft robotics.

With extensive in-house expertise, Sygnis SA excels in using silicone for DIW. They have successfully partnered with industry leaders to print various items like gasket seals, enclosures for harsh environments, and thermal-insulating sockets.

3D printing with silicone is transforming many industries by leveraging its flexibility, biocompatibility, and durability. In healthcare, medical-grade silicone is used to improve prosthetics and personalized implants. The automotive and aerospace sectors benefit from custom gaskets and seals. Beyond DIW, techniques like direct motor-driven extrusion and inkjet printing with silicone-based inks or pastes are also employed for precise layer-by-layer deposition.

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up