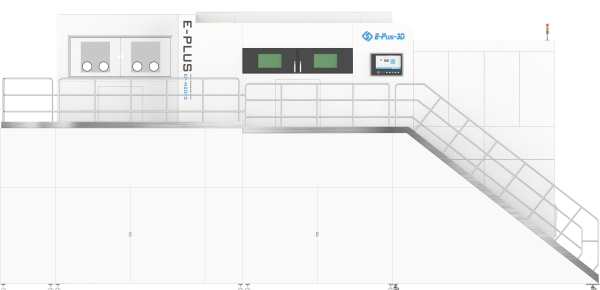

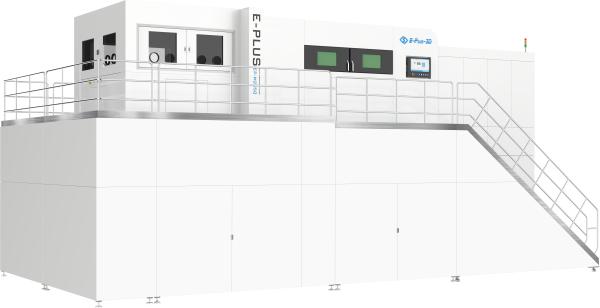

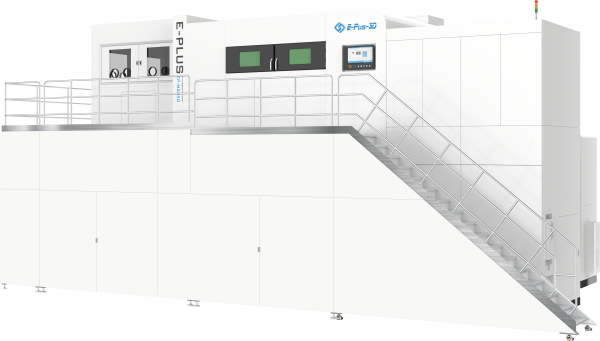

Large-format metal additive manufacturing system featuring 36 lasers.

Home » 3D Hardware » EP-M2050 Metal 3D Printer

The EP-M2050 utilizes Metal Powder Bed Fusion (MPBF™) technology, featuring a spacious forming chamber reaching up to 2050 x 2050 x 1100 mm (with a customizable Z-axis up to 2000 mm). With 36 lasers and galvanometers, it employs multi-laser precision positioning and precise control of overlapping areas. Compatible with a range of materials including titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, cobalt chrome, and copper alloy, the EP-M2050 is an ideal solution for manufacturing large-size, high-precision parts for aerospace and related industries.

Machine Model | EP-M2050 |

Build Volume (X x Y x Z) (height incl. build plate) | 2050 x 2050 x 1100 mm (80.71x80.71x43.31 in) |

Optical System | Fiber Laser 36 / 49 / 64 x 500 W (700 W is optional) |

Spot Size | 70 - 120 μm |

Max Scan Speed | 8 m/s |

Layer Thickness | 20 - 120 μm |

Theoretical Printspeed | Up to 1080 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Power Supply | 380 V, 50 / 60 Hz, 117 kW |

Gas Supply | Ar / N2 |

Oxygen Content | ≤ 100 ppm |

Dimension (W x D x H) | 12685 x 7185 x 6530 mm |

Weight | 145000 kg |

Software | EPControl, EPHatch |

Input Data Format | STL or other Convertible File |

WhatsApp us

Thanks for signing up