The orthodontic industry is shifting gears by implementing new 3D production methods in the field of stomatology.

The goal is to move production toward total digital processing and manufacturing. While pursuing more comfort and beauty, brace less and the invisible orthodontics and now being offered to customers, utilizing this new 3D printing technology.

As computers and software improve so does orthodontic systems continue to evolve, offering patients an aesthetic and comfortable orthodontic experience. As more patients opt for invisible orthodontics, the group of users increases exponentially.

The availability of invisible orthodontics is responsible for the industry accelerated development and growth. With promising industrial prospects and the benefits of 3D technology, the orthodontic industry is expected to explode in the future. Current 3D print technology is capable of producing precise dental models, allowing for technically reliable and comfortable invisible braces.

Leading enterprises of the orthodontic industry report an overall cost reduction in the year 2020 of 35% labor costs, decrease in production costs by 9.7%, while in 2019 it was 3.5%. Experts explain the reduction due to the scale effect mostly attributed the move to fully automate the entire production line and replace manual labor.

How to build the fully automated production line?

Automating the Digital 3D manufacturing solution

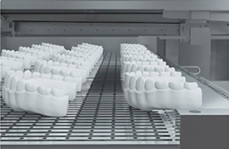

Current 3D print technology already offers a host of solutions to produce an accurate 3D dental prototypes, used as the hot press mold for the production of invisible braces. UnionTech offers an automated digital 3D printing solution for the orthodontic industry.

It consists of:

Automatic typesetting

made by Polydevs. This powerful Pre-processing software is capable of generating optimized nesting solution, 3D slicing and exporting print files to be fed to a 3D printer.

Automatic 3D Printing

made by UniunFab, an Internet cloud based manufacturing platform. It includes an intelligent production scheduling, model repair, remote equipment monitoring, and health management. Also included are production data analysis and process standardization management.

Automatic Recycling

An intelligent detection process that filters out the defective models from the print batch and assures an effective cleaning of surplus materials to be recycled.

Automatic resin refilling

an automated resin feed to each of the 3D printers from a central resin supply reservoir assures continuous and reliable operation.

An automated internet based platform optimized for the Orthodontics industry

Powerful toolset to unlock fully automated production

- Automatic Bp: Support BP v3/v5, distributed Executors and Batch Execution.

- Batch Remote Print: Supporting start printing on many 3D printers concurrently.

- Remote OPS: Live observation of working printers and command execution remotely.

- Offline First: Remote Login is possible from any cloud based as well as offline environment.

UnionFab, is a 3D printing cloud manufacturing platform, able to upgrade an orthodontic production by offering an intelligent solution to the entire manufacturing process quickly and at a very low cost. It includes, intelligent quotation, Customer service and order management, data assist, optimized production scheduling, remote production and digital management. This automation is sure to improve customer service experience an increase production efficiency of the entire enterprise operation.

At its core UnionFab offers:

- Adapting new highly efficient production method

- Optimized relevant 3D data and pre-production

- Detection delict management of production information

- Compatibility with IT management requirements

- Easy implementation and usage

UnionTech is at the cutting edge of 3D additive manufacturing technology, specializing in the field of SLA 3D print technology in many diversified industries. UnionTech will continue to research, develop and improve 3D printing solutions to the orthodontic industry. OnionTech is constantly at the leading edge of 3D print technology, forging forward, making the impossible into possible.