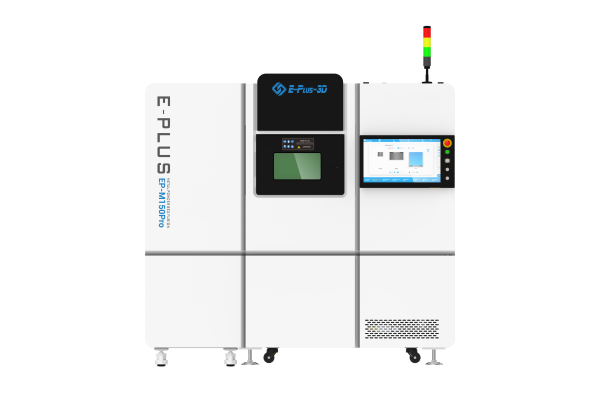

Equipment for the production of metal additives characterized by exceptional speed and precision.

Home » 3D Hardware » EP-M150Pro Metal 3D Printer

The EP-M150Pro utilizes metal powder bed selective melting MPBF™ (Metal Powder Bed Fusion) technology, with optional single and dual-laser printing modes for rapid production of high-performance, high-precision parts. Compatible with popular metal powder materials like titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, cobalt chrome, and more, it finds applications in industrial manufacturing, medical, education, dental, materials development, and beyond.

Machine Model | EP-M150Pro |

Build Volume (X x Y x Z) (height incl. build plate) | Φ 150 x 225 mm (Φ 5.91 x 8.86 in) |

Optical System | Fiber Laser 500 W (single or dual-laser optional) |

Spot Size | 70 μm |

Max Scan Speed | 8 m/s |

Layer Thickness | 20 - 120 μm |

Theoretical Printspeed | Up to 55 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, etc. |

Power Supply | 380 V, 50 / 60 Hz, 12 / 13.5 kW |

Gas Supply | Ar / N2 |

Oxygen Content | ≤ 100 ppm |

Dimension (W x D x H) | 2120 x 980 x 2250 mm |

Weight | 1500 kg |

Software | EPControl, EPHatch |

Input Data Format | STL or other Convertible File |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up