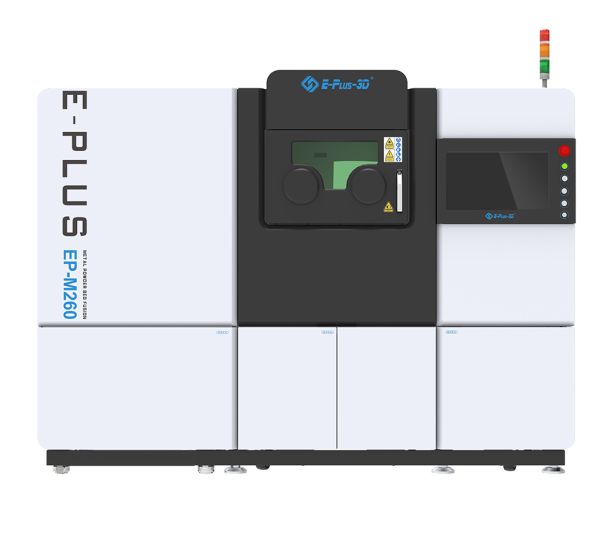

A capable industrial metal 3D printer, an ideal solution for medium size 3d printed parts and small batch production.

Home » 3D Hardware » Eplus3D » EP-M260 Metal 3D Printer

An ideal additive manufacturing solution for medium size 3d printed parts and small batch production, the EP-M260 is a capable industrial metal 3D printer, using advanced metal powder bed fusion (MPBF) technology. Offering high 3d parts precision, fast production and efficiency, EP-M260 3D printer is an ideal choice, ready to make any CAD idea into a physical reality.

Utilizing an innovative gas flow management and efficient filtration system, the EP-M260 is a stable building environment, while keeping oxygen at an optimized level. Using Dual-Laser system and a build volume of 266x266x390mm³, the EP-M260 is made to run non-stop, producing high quality 3d printed parts. Intelligent software driven operation, minimizing human touch, while monitoring print operations.

Designed to minimize material waste, advanced filtration system to extend filter lifecycle and low inert gas consumption, the EP-M260 is a cost-effective 3D printer to operate.

Machine Model | EP-M260 |

Build Chamber (XxYxZ) | 260 x 260 x 390 mm (10.24 x 10.24 x 15.35 in)(height incl. build plate) |

Optical System | Fiber Laser, 500 W / 700 W (single or dual-laser optional) |

Spot Size | 70~100 µm |

Max Scan Speed | 8 m/s |

Layer Thickness | Up to 55 cm³/h |

Theoretical Printspeed | 20~120 µm |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | - |

Power Supply | 380 V, 24 A, 50 / 60 Hz, 5 kW |

Gas Supply | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm |

Dimension (WxDxH) | 2800 x 1300 x 2410 mm |

Weight | 2300 kg |

Software | EP Control, EP-Hatch |

Input Data Format | STL or other Convertible File |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up