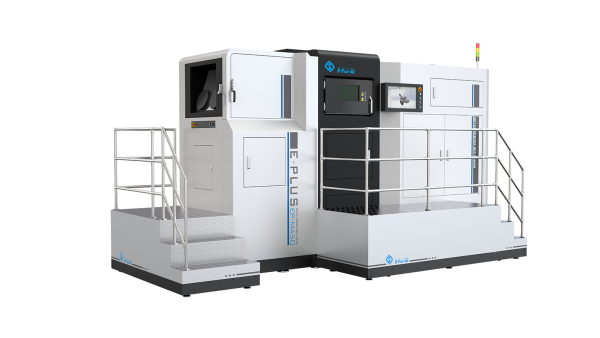

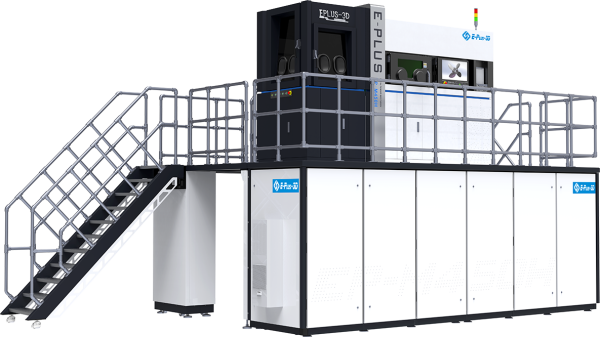

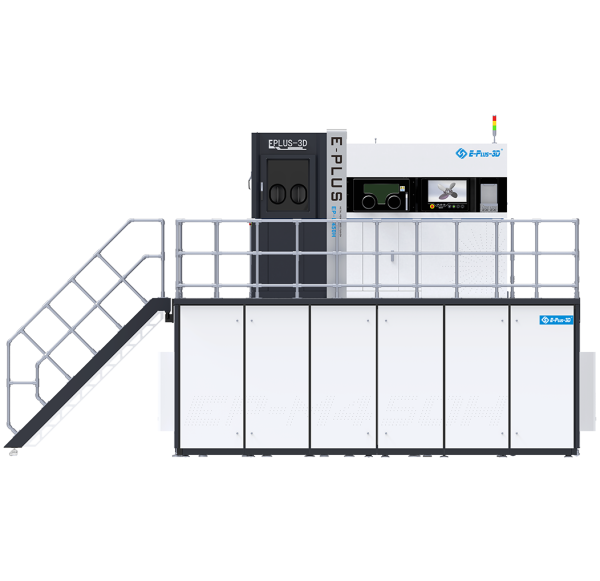

Large Size & High Speed & Reliable Production Metal Additive Manufacturing System

Home » 3D Hardware » Eplus3D » EP-M450 /EP-M450H Metal 3D Printer

For uncompromising 3D Metal printers of reliable and high quality large metallic parts on par with the highest industrial demands, the EP-M450H (455*455*1100 mm³), and EP-M450 (455*455*500 mm³) 3D printers offer a large print volume ready to tackle production challenge.

The EP-M450 series 3D printers are capable of printing large metal parts at very high precision, achieving max <5% mechanical deviation. Chamber gas management eliminates smoke and splashes, achieving a uniform and consistent prints. An Intelligent control software dynamically applies different scanning algorithm and print parameters to different sections of the printed part, optimizing output. Variable layer height output is available to further speed up print time yet maintain an uncompromising small detail of final parts.

Using high quality laser optics and accurate motion control system, sealed print chamber, stable oxygen concentration of <100 PPM, assures accurate output. Consistent print monitoring system assures steady supply of print material for reliable and an uninterrupted continues printing.

User intuitive and friendly slicing and printer control software featuring one-click printing, simplify the parts prep and printing procedures. Comparability with different types of re-coater blades such as ceramic, PU, alloy steel etc. Process software can be integrated with Siemens NX software to realize effective planning of design, simulation and printing path planning, within one software and highly improving the production efficiency.

-600x425.png)

-600x337.png)

-100x100.png)

-100x100.png)

Machine Model | EP-M450 | EP-M450H |

Build Chamber (XxYxZ) | 450 x 450 x 550 mm (17.72 x 17.72 x 21.65 in) | 450 x 450 x 1080 mm (17.72 x 17.72 x 42.52 in)(height incl. build plate) |

Optical System | Fiber Laser 500 W / 2 x 500 W / 4 x 500 W (700 W and 1000 W are optional) | Fiber Laser 500 W / 2 x 500 W / 4 x 500 W |

Spot Size | 70~130 µm | 70~130 µm |

Max Scan Speed | 8 m/s | 8 m/s |

Layer Thickness | 20~120 µm | 20~120 µm |

Theoretical Printspeed | Up to 190 cm³/h | Up to 190 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | - | - |

Power Supply | 380 V, 30 A, 13.3 kW, 50/60 Hz | 380 V, 23 kW, 35 A, 50/60 Hz |

Gas Supply | Ar / N₂ | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm | ≤100 ppm |

Dimension (WxDxH) | 5670 x 3700 x 3325 mm | 6410 x 3670 x 4850 mm |

Weight | 10000 kg | 15000 kg |

Software | EP Control, EP-Hatch | |

Input Data Format | STL file or another convertible format |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up