Compact depowdering unit for powder removal of metal laser melted parts

Home » Post Process » Solukon » SFM-AT200

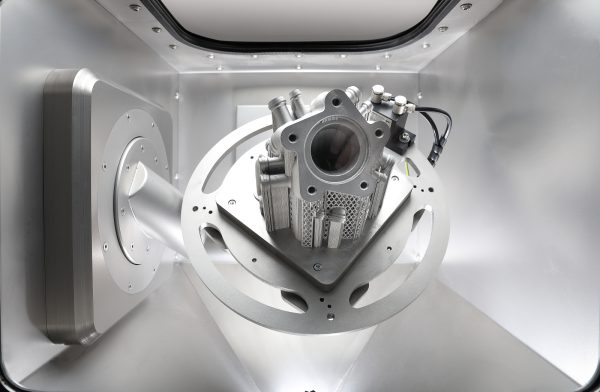

The SFM-AT200 cleans metal laser-melted parts within a sealed process chamber, with targeted vibration and automated rotation.

Due to rotation of the parts, including the build plate, unmelted build material is removed from complex voids and support structures.

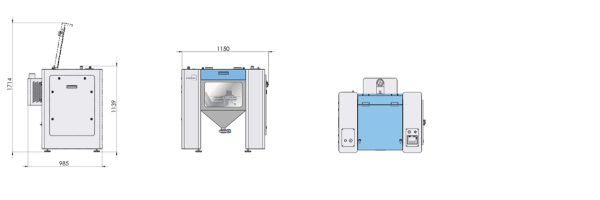

The compact design of the SFM-AT200 optimizes the footprint as well as the consumption of inert gas.

The internal stainless steel design makes the SFM-AT200 the ideal cleaning system for medical components with high cleaning requirements.

The depowdering system is based on the unique Solukon Smart Powder Recuperation® technology.

Installation space (W x D x H) | "2,200 x 2,400 x 2,200 mm" |

Weight | 150 kg |

Mains voltage / frequency | 400 / 50 - 60 V / Hz |

Power consumption | 0.4 kW |

Power supply | 16 A |

WhatsApp us

Thanks for signing up