Compact depowdering unit for powder removal of metal laser-melted parts

Home » Post Process » Solukon » SFM-AT350

The SFM-AT350 cleans metal laser-melted parts within a sealed process chamber, with targeted vibration and automated two-axis rotation.

Through programmable rotation of the parts, including the build plate in two axes, metal powder is also removed from complex voids and support structures.

After the automated cleaning program, manual cleaning with compressed air or inert gas is possible via glove ports.

The depowdering system is based on the unique Solukon Smart Powder Recuperation technology SPR®.

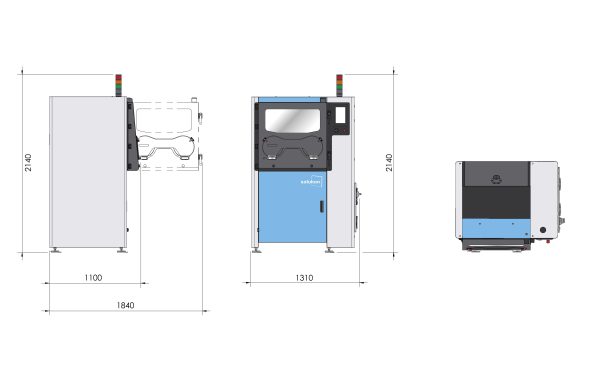

Installation space (W x D x H) | 2,300 x 2,300 x 2,300 mm |

Weight | 420 kg |

Mains voltage / frequency | 400 / 50 - 60 V / Hz |

Power consumption | 1.0 kW |

Power supply | 16 A |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up