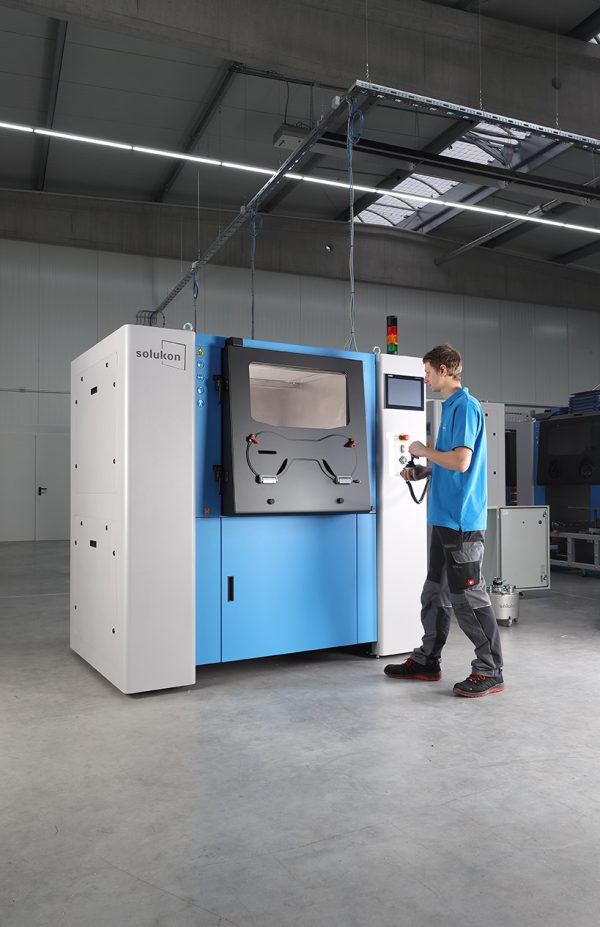

Depowdering system for automated powder removal of metal laser-melted parts

Home » Post Process » Solukon » SFM-AT800 / -S

The SFM-AT800 cleans metal laser melted parts within a sealed process chamber, with targeted vibration and automated two-axis rotation.

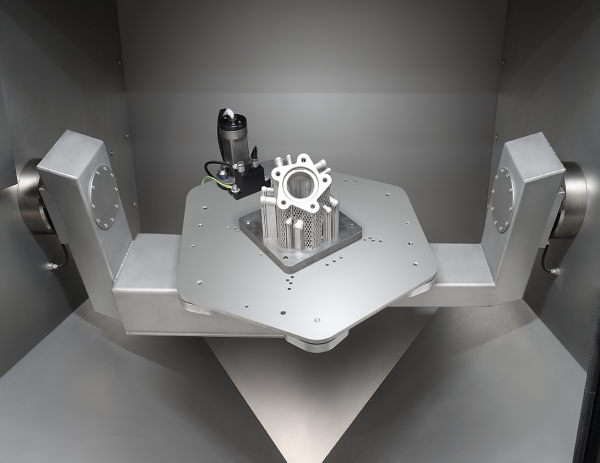

Through programmable rotation of the parts, including the build plate in two axes, metal powder is also removed from complex voids and support structures.

The SFM-AT800-S is a special version of the SFM-AT800. It is equipped with two endless rotating axes with two programmable servo-drives and can move the part along any imaginable path.

Both systems are based on the unique Solukon Smart Powder Recuperation® technology.

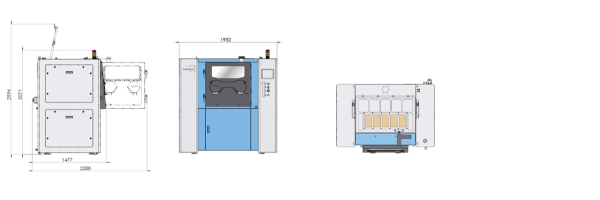

Installation space (W x D x H) | 3,500 x 2,500 x 3,000 mm |

Weight | 900 kg |

Mains voltage / frequency | 400 / 50 - 60 V / Hz |

Power consumption | 0.4 / 1.5* kW |

Power supply | 16 A |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up